Re-Pelletizing system from Plastic Waste in Moulding Plants

MTIL offers Re-Pelletizing System for Plastic Waste in Molding Plants.

System - Summary:

- Reliable: Ensures stable drying condition with honeycomb rotor. Independent drying and conveying circuits allows conveyance of materials without affecting drying condition.

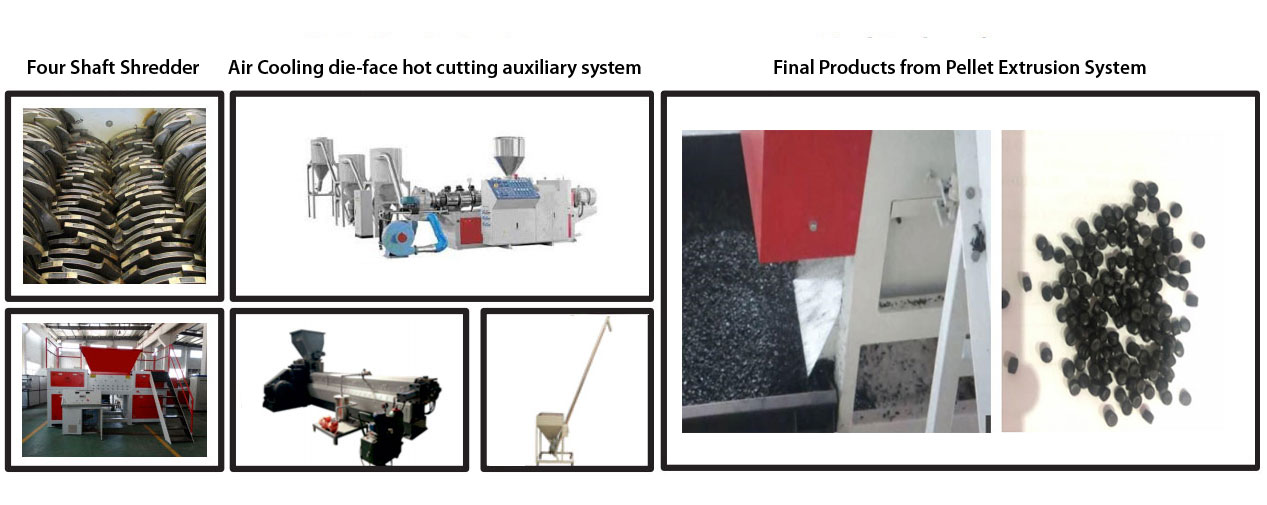

- Lumps & Heavy Plastic pellet Shredder –Capacity Up-to 500-700 Kg/hr.

- Pellet Extruder Capacity up to-500-600 Kg/hr

- Conveying Line with different blowing stations.

- Spiral Conveyor

- Air cooling die face hot cutting Auxiliary System Electric Panels for intergradation

Working:

- Crushed Lumps, Ext Crushed Lumps, External & Internal Auto Parts as well as Heavy Plastic Parts like Pellets, Drums, etc. into small cut sizes accordingly Re-Palletized with the Extruder Line & use in Plastic Molding as well as Virgin Material.

- Shredded plastic also used in road construction for longevity & durability inability in a homogenous mixture with an educated amount with Charcoal.

- Shredded Plastic also used in Pyrolysis Process for making different fuels as Biogas, Polyethylene Oil, Charcoal waste for using in different Industrial Processes like Boiler Fuel, Turbine Gaseous Fuel, Industrial Plants.