MTIL, your Plastic Molding partner for resource reduction, proposes to achieve ‘factor 4’ in Molding process by enhancing 4 times productivity with half resources in terms of saving Water, Resins & Energy.

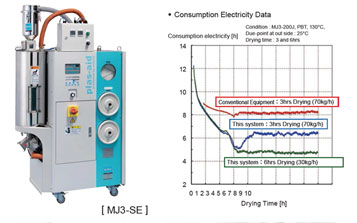

Valve-Type Drying Adjustment System (For MJ3)

Does it make sense to run a dryer at 100% capacity in every situation? Energy savings of up to 40% are possible when it is added to an existing dryer!

A Dryer with intelligence is now offered by MTIL. Adaptive controls eliminate wasted energy.

Some resins degrade if exposed to heat for extended periods. This is sometimes called “over-drying” and can be prevented with our Valve Optimizing System.

Drying and Regeneration airflow rates are automatically adjusted according to the demand from the molding process. This dryer realizes ultimate energy savings by adjusting to the needs of the molder. System heaters use less power as airflow drops when molding demand slows.

Salient Features

- Adjusting airflow rates based on temperatures is the best method for saving energy & protecting resin.

- Additional power is saved by minimizing heat escaping to plant which reduces the air-conditioner load.

- The Valve Optimizing System can be retrofitted to existing machines (MJ3).

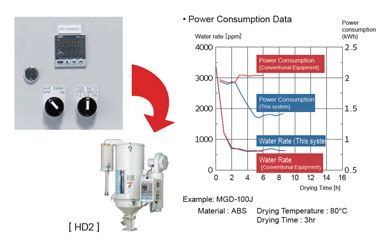

Inverter-Type Drying Adjustment System (For HDI)

Does it make sense to run a dryer at 100% capacity in every situation? Energy savings of up to 40% are possible when it is added to an existing dryer!

MTIL offers Inverter-Type Drying Adjustment System which can be used for optimizing drying in hopper dryer by monitoring the exhaust temperature.

Resins can be dried with minimum energy by controlling the air flow rate. The consumption of heater can reduce to a minimum level.

Salient Features

- This will prevent over-drying of materials if the molding machine should stop unexpectedly.

- The exhaust temperature is recycled, thus saving the energy required for air conditioning.

- The energy savings mode is selected using one switch.

Rapid Heat Cycle Molding (RHCM®) (Steam)

MTIL offers Rapid Heat Cycle Molding (RHCM®) (Steam) which adds additional value by improving the welded part strength, reduces parts sticking in the mold, allows decals in the mold, improves visual quality (coatless), fillers will not be seen, reduces warpage, deformation of the part, and relaxation of the part.

MTIL provides the most advanced improvement of parts quality for specifically designed molds. From the possibility of divided set up the manifold unit (open), even divided set up after variance of layout rise, it will have no effect on the heating cycle. Mold will be heated by high efficiency because steam will be supplied to manifold directly.

Salient Features

- Temperature rise 2.5-6 times with steam versus water type system.

- Temperatures rise more uniformly in a shorter time period on mold surfaces by the use of specifically designed molds.

- Molding assistance is available at a cost from the Alliance.

- New facilities can introduce Heat & Cool (RHCMR).

Eliminating Contamination

There is a possibility of some contaminations at all processes. Material Tank is first contaminant mixing source.

MTIL offers Material Tank with clean specifications for contaminant prevention. This is the column structure for easy cleaning and prevents contamination by filter which attached a part of fresh air admission port.

Salient Features

- Exclusive design special surface material.

- Each filter can be set exclusively (Example: 20μm Cut, Optics: 0.3-0.1μm)

- This supports various sizes such as paper bags and flecon receiving models, etc.

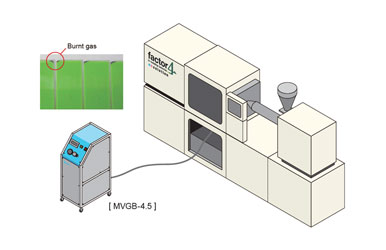

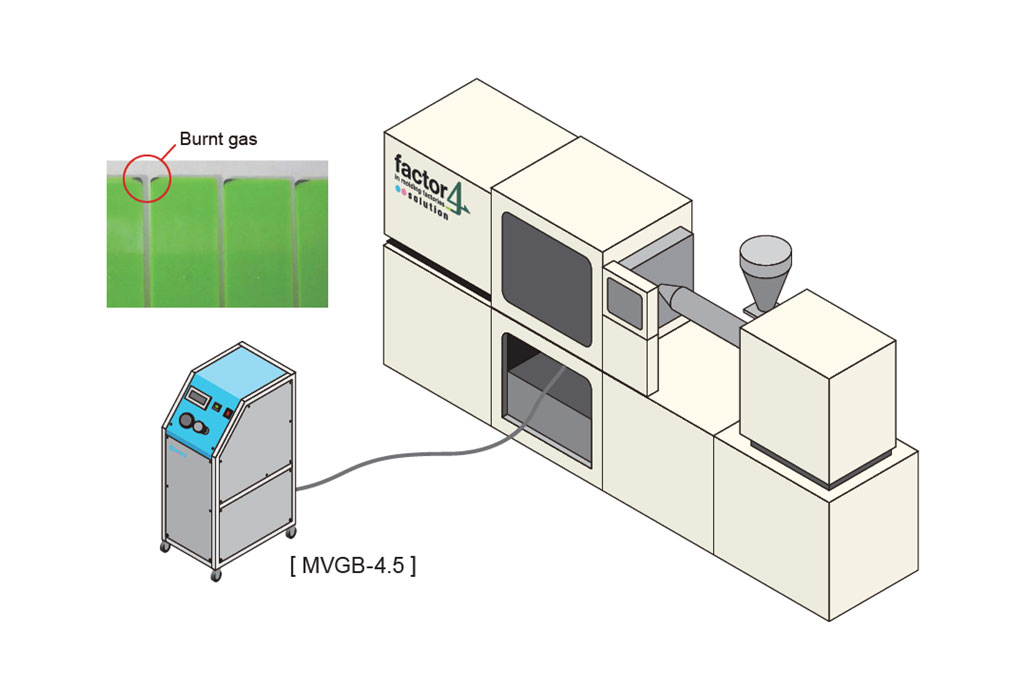

Gas Booster with Vacuuming Function

MTIL offers a solution for Gas Removal from inside Mold Cavity through a porous frame, a backwash is created by pressure to remove gas and air.

Gas Booster is a vacuum and pressure unit that uses compressed air. It sucks gas and air that collects in the mold by vacuum and exhausts it. Prevents gas adhesion to gas bend and porous part. It is possible to improve productivity for new application which is inserted hoop molding.

Salient Features

- Can pull out gas by vacuum ejector.

- Air booster can increase the pressure up to 4.5MPa.

- Uses backwash at the gas bend and porous part to prevent from the gas plug.

- Unique controls allow for the setting of optional operation.

- Fixes metallic worm in hoop molding and prevents bad positioning and bite crowd.

- By reducing air pressure at the mold, the number of prominent pins will likely decrease.

Granulator Equipped with Super Easy Cleaning Device

MTIL offers Granulators equipped with Super Easy Cleaning Device to have a big advantage over conventional machines.

The Super Easy Cleaning Device uses high-pressure air to remove dust and fine powder that can cling to chamber surfaces. Many times it isn't possible to remove these contaminants with a vacuum or cleaner. Cleaners are unnecessary when changing jobs because the material loader performs this function.

Salient Features

- The unique design makes it possible to safely open & close the cutting chamber.

- Cleaning is completed within 99 seconds. (Can differ by the material.)

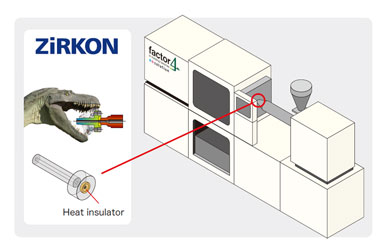

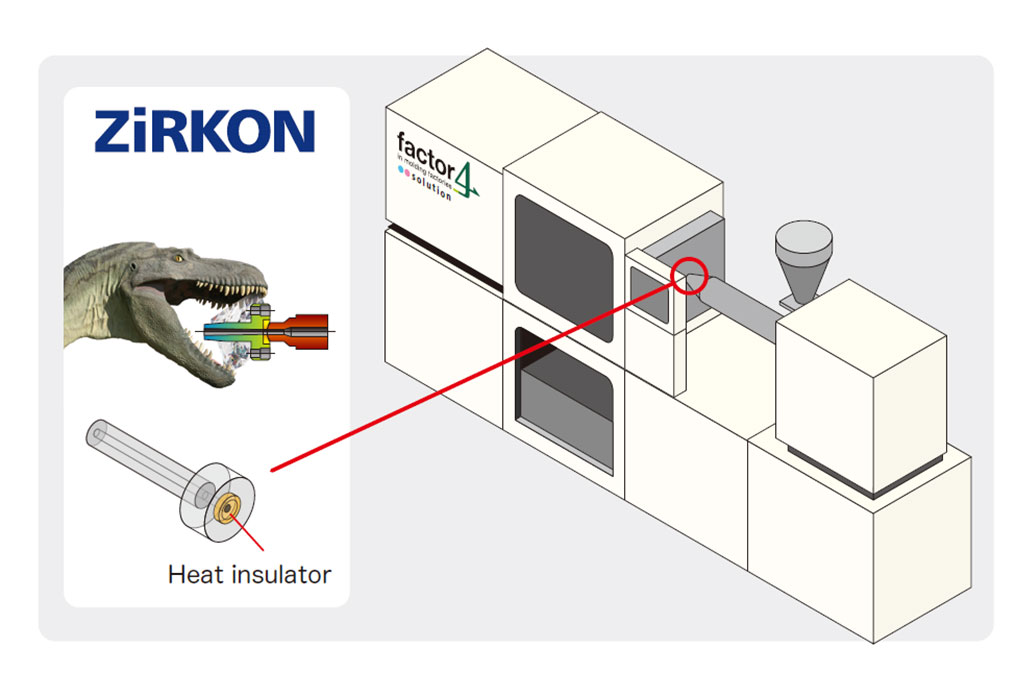

Adiabatic Sprue Bush (ZiRKON)

MTIL offers a solution to resolve a problem of stringiness by using Adiabatic Sprue Bush (ZiRKON). It helps to stabilize nozzle temperature and quality.

This is Sprue Bush was developed to prevent stringiness on LCP molding. Uses a heat insulator (ceramic) between the mold and injection nozzle. Control temperature from the nozzle and stable molding is possible.

Salient Features

- Stringiness is prevented by stopping the temperature inlet to mold by a nozzle. Particularly, the effect shows on stringiness prevention and stable forming when the nozzle temperature is high.

- Cuts resin loss in the start-up. (There are few loss shots).

- Wiring and piping work is easy.

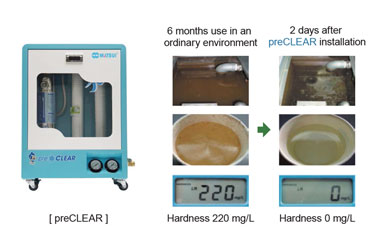

Ion Exchanger Water Softener with Filter

MTIL offers "PRECLEAR” Ion Exchanger Water Softener with Filter to resolve the problem of Green Algae, Sludge, and Choking of Mold Cooling Holes while using MTC, broken impeller, broken mechanical seal, if damage to the heater occurs.

Water softener consisting of a filter to remove suspended substances that cause corrosion to progress, and an ion exchanger with filter to remove scale deposits. Ensures reliable production and helps extend the operating life of cooling lines.

Salient Features

- Practically maintenance-free.

- Operates by simply adding to existing lines.

- Filter removes suspended substances.

- Prevents build-up of scale.

- The filter and ion exchange resin are cartridge types, which makes replacement very easy.

- Saves water and reduces maintenance costs.

Digital Water Flow Sensor

Fluids are used all throughout facilities, each with its own usage and purpose.

Example: Water to cool a die in an injection Molding machine.

There are some factors that cause variations in flow and lead to inconsistent flow amounts such as a clogged basket in the strainer may lead to slower flow and improper valve control can lead to very costly mistakes.

MTIL offers Clamp-On Digital Water Flow Sensor which provide several layers of benefits for any flow application.

Salient Features

- It can be mounted in 60 seconds without any pipe modification. The unit clamps on to the outside of a pipe with 6 standard screws and can even be done without shutting the machine down.

- It can detect virtually any type of liquid. This includes the flow of water (including deionised), oils, chemicals, consumer products, etc. This detection is possible through both metal and resin pipes.

- Contamination, pressure loss, leaks, continual maintenance and machine downtime are all risks associated with conventional flow sensors that are avoided with it.

- By pairing it with a MU-N controller, a separate display can be utilised, as well as increased functionality, in an easily accessible location.

Aero Power Hopper (APH)

MTIL offers Aero Power Hopper (APH) which is a vacuum hopper which blends material by using pneumatic conveying air from the blower. Remove dust. Improve product quality. Mix resins and colors. A simple design that sits right on the molding unit.

The APH removes dust and fines by thoroughly mixing resin while a vacuum suctions dust particles from above. It also evenly mixes two resins prior to molding, maximizing productivity and product quality, and minimizing rejects. Easy-to-install directly on the molding unit, is saves time and space.

Salient Features

- Best suited for molding with dust and foreign material removal

- Utilizing conveyance power for blending (no additional power needed)

- Material blends right on the injection-molding machine (no segregation during conveyance.)

- Simplified structure offers easy cleaning.

- No cracking or electrostatic charge of mechanical blending.

- Built-in a hanging type flap damper with biting prevention function while improving mixing performance with dust removal.