MTIL provides an extensive range of auxiliary equipment for the plastics processing industries with its products finding applications in a spectrum of industrial applications including,

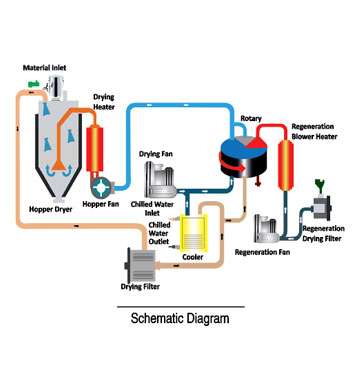

Dehumidifying Dryers

MTIL Dehumidifying Dryers provide a stable low dew point dryer and a suction loader on a single platform. This floor type device puts its priority on easy maintenance. As there is no need to replace the absorbent material, performance is being maintained like that of the first usage.

- Reliable : Ensures stable drying condition with honeycomb rotor. Independent drying and conveying circuits allows conveyance of materials without affecting drying condition.

- Saves Energy Dual hopper structure enhances thermal insulation and hence, helps conserve energy.

- Compact Combine dehumidifying dryer and conveyor into a single unit.

- Easy Maintenance All filter maintenance can be done from the operating side.

- Safe Heater control circuits are equipped with SSR (non-contact relay), which is safer and reduces the need for maintenance.

Hot Air or Hopper Dryers

MTIL Hot Air or Hopper Dryer is a ventilation typed device that dries resins with hot air. The hot air of high pressure rises as it goes in between resins and thus, is capable of uniformed drying in a short duration.

- Reliable : Air drawn in by the blower goes through the heater of a rectified flow and is spread evenly from the discharge port. Hence, the difference between the set and actual temperature is being minimized. MTIL's original diffuser cone prevents the short passing of materials.

- Safe The voltage tripping breaker (SHT type) trips upon overheating. A preventive device for external overheating comes together as an independent safety device from the temperature controller.

- Saves Energy The dual structure of the heater box supports both heat exchange and thermal insulation. The dual structure of the lower hopper, whose temperature rises to the highest, prevents heat radiation.

- Easy Maintenance While hopper bodies of small models can be opened via the hinge, hopper bodies of the bigger models are equipped with a large maintenance window for easy cleaning.

- Environment Friendly The long-lasting, easy to detach filter sheet keeps the molding environment clean.

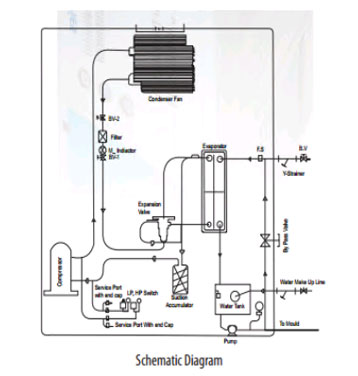

Compact Chillers (Air Cooled & Water Cooled)

Chiller is specially designed for various applications that ensure stable process temperature with a high flow rate and pressure.

Salient Features

- Wide range temperature control 7˚C-25 ˚C

- Use of high-flow, high-pressure pump

- Compact Design

- Scroll Compressor

- Compressor On/Off delay temperature ±3 ˚C

- Insulated Water Tank

- Evaporator flow switch

- The visual indication for the main functions

- Y-Strainer at the pump suction

- Ease in maintenance

- Sight glass for easy monitoring of the refrigerant state.

- SUS Pump for better circulation & long life.

- Flexible piping in the Refrigerant monitoring connection for a better life.

- Uses ‘R407C’ Refrigerant Gas as the cooling medium that does not harm our ozone layer.

Central Chillers

ADVANCED WATER COOLING SOLUTIONS FOR COMMERCIAL & INDUSTRIAL USE

The new highly efficient MTIL Water Cooled Central Chiller with Eco-friendly ‘R-407C’ Refrigerant Gas as the cooling medium, delivers impressive performance and ensures flawless functioning.

Key Features

- Highly Reliable Shell & Tube Heat Exchanger

- Eco-friendly ‘R-407C’ Refrigerant Gas

- Precise control functions

- Low Vibrations and Low Noise

- High-performance Compact Screw Compressor

- Built-in Safety Features

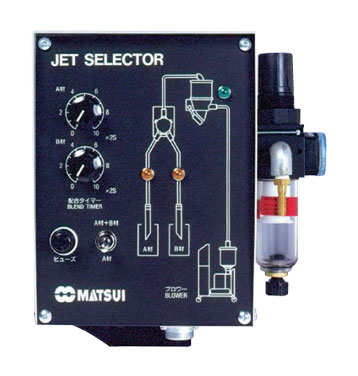

Vacuum or Jet Loader

It provides a stable conveyance of materials automatically that supports the management of material conveyance. In addition, the reduction of manual feeding ensures greater safety.

Vacuum or Jet Loader is a vacuum material conveyor that separates foreign objects from materials in the suction hopper and collects dust from the air before emission. Best suited for the conveying of material from multiple points to one destination.

Salient Features

- Compact design

- Touchpad type control panel with digital display.

- Counter that informs filter cleaning cycles.

- The large dust box reduces the frequency of maintenance.

- The cyclone typed dust separator reduces the need for maintenance of filter.

- It also supports long hours of stable conveyance.

- Minimized metallic and conveying noises to less than 80db.

- Castor wheels with brakes.

- Multi-directional conveying-up to 6 Hopper Loaders as option.

- Stainless Steel Hoppers

- Hoppers with provision for a minimum reserve of material with sight window (MVH).

- Special hoppers for dust removal and blending (APH).

Slow Speed Granulator

SMGL is the standard for the low-speed granulators. The non-screen construction reduces the formation of powder and miscuts thereby giving the end product uniformed grain size.

Reliable

- Reducing shaft stress, double bearing eliminates difficult adjustment, extends the lifespan of bearing, and makes the exchange of blades and bearing easier.

- The use of anti-vibration torque arm extends the lifespan of bearing and reduction gear.

Easy Maintenance

- Sight glass has been included as a regular feature for the supervision of granulation.

- Dust wiper prevents fine granulated materials from getting into the bearing. Air purge can also be used manually.

Safe and Environmental Friendly

- 2 limit switches are located at the opening and closing part of feeding hopper

- A motor breaker prevents excessive load.

- Soundproof steel used for feeding hopper reduces noise pollution.

Medium Speed Granulator

SMGM is the standard for the medium-speed granulators. The non-screen construction reduces the formation of powder and miscuts thereby giving the end product uniformed grain size.

Reliable

- Reducing shaft stress, double bearing eliminates difficult adjustment, extends the lifespan of bearing, and makes the exchange of blades and bearing easier.

- The use of anti-vibration torque arm extends the lifespan of bearing and reduction gear.

Easy Maintenance

- Sight glass has been included as a regular feature for the supervision of granulation.

- Dust wiper prevents fine granulated materials from getting into the bearing. Air purge can also be used manually.

Safe and Environmental Friendly

- 2 limit switches are located at the opening and closing part of feeding hopper

- A motor breaker prevents excessive load.

- Soundproof steel used for feeding hopper reduces noise pollution.

High Speed Granulator

Produced with CE certification and soundproof technology, our high-speed granulator is to lower dust generation, reduce noise levels, and increase worker safety and provide users with a huge saving in energy costs as well.

Salient Features

- Noise insulation

- Fail safe

- Attained the CE marking.

- Verified to have cleared the requirements in terms of safety level, hygiene, noise and electromagnetic waves.

Shredders

MTIL provides a hybrid type of shredder shredding and granulating to do at once. In the shredding rotor with a large bosom, and then fed to the shredding blade finish to ensure the thing caught up once. In the slow shredder, and could not be shredded is now available for granulating.

- Improve Granulating Efficiency : Shredding rotor is excellent in entrainment, you can tuck in without granulating long objects.

- Fewer Miss-Cut : There are no miss-cut long runners to pass through the screen as a high-speed granulator. Friction is small and stable grain size was also less powder.

- Improve Cleaning : Feeding hopper is wide open, cleaning is easy because you can open the casing milled greater.

- Low Noise : Rotor shredding impact sound will be smaller for (26.6rpm/60Hz) low-speed rotation. Granulating blade is a low noise for (106rpm/60Hz) rotation speed of the helical blade.

- High Processing Power : Granulating Capacity (Approximate) 60 ~ 100kg / h

- Space-Saving : Compact has been realized by a single machine to aggregate shredding and granulating capabilities.

- Safety : Two to feeding hopper, one tank, and one part of the casing milled, to adopt one of the chain cover interlock limit switches, the motor breaker was standard equipment for overload protection.

Material Tank & Silos

The Material Tanks TA is available in 3 sizes, ranging from 55 ~ 175L, and the T is 2-type (350L, 600L). It is an environment friendly, functional, and easy to clean.

Salient Features

- Noise insulation

- Easy Cleaning

- Multi-Function

- Reliable

In the long term, Silos are the most cost-effective solution for an intermediate storage of plastics when large quantities are processed.

We manufacture Silos as per customer requirement and capacity.

Blenders

With feed optimization software coupled with completion forecasting signals, MTIL’s Blenders reduces resin waste by as much as 99%. Automatically regulates flow volumes to suit the molding machine’s status, greatly reducing waste with the disposal. Reduces cleaning time and labor when materials or colors are changed.

Salient Features

- More compact and space-saving : Roughly half the installation footprint while ensuring maximum capacity.

- Simple Operation : User-friendly interactive operation.

- Automatic Operation : Even when there is a change in material, this device automatically detects and alters the measurement conditions to accommodate the new material.

- Easy Cleaning : The hopper and screw can easily be removed, thus making cleaning up easier.

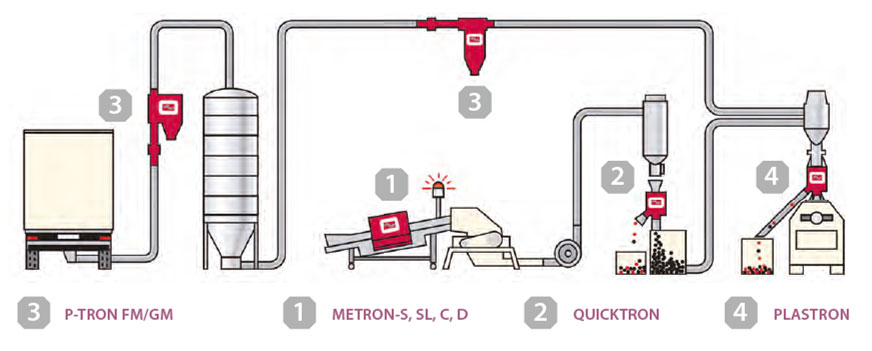

Centralized Conveying System

We plan, manufacture, and install our central material supply system – designed completely according to our customer wishes and adapted to their plastics processing. Buying, operating, and maintaining two or three central dryers are more efficient than doing the same for ten, twenty, or fifty dryers on individual processing machines. As great as that cost advantage maybe – energy savings alone may justify it – cost reduction is but one of many compelling reasons to go central.

Benefits

- Precisely dried material, process stability, less waste, fewer quality issues.

- Cost-saving, with less personnel

- Continuous operation without downtimes

- No material-related traffic on the shop floor.

- Energy savings with one central dryer vs. many smaller dryers.

- Energy reductions can earn substantial rebates from utility suppliers/government.

- Floor space for gay lords, dryers, etc. can hold new value-adding machines

- Loading the wrong material into a machine can be virtually eliminated.

- Maintenance is reduced due to having fewer machines.

- Safety improves with clear passages and much less climbing on machines.

- Faster changeovers thanks to built-in purging increases uptime

- Process troubleshooting is easier with assured material conditioning

- Control is simplified and more comprehensive.

- Central material management without the danger of confusion

- Clean production due to no residues on the machines

- The modularity makes the system expandable and future-proof

Ecobrid - Air-cooled Closed Circuit Water Cooling System

Ecobrid supplied by MTIL is an Air-cooled Closed type Water Cooling System that has high functionality, cost-efficient, and environmentally friendly. 5000 sets are already in operation with satisfactory results.

Salient Features

- Energy saving

Saves energy by optimizing the operation of the system. This saves more than 30% of the energy consumed as compared to the regular system maintenance. In addition, the noise level during operation is being controlled under 57db. - Easy maintenance

Water in the system is being drained out automatically without using valves. This prevents freezing and cracking of pipes during resting periods of the factory when external temperature falls below 0oC. - Safety

Upon the occurrence of an error, the cause and solution will be displayed as the warning signal. This allows a smooth resolution of the problem. The management of the production line is also made possible. - Unifying of units

Control panel, tank, valve, and other units are being unified into this single unit. This saves space and allows speedy operation. A high level of durability of the pump unit and cooling tank is made possible with stainless steel.

Dosing Units

Save money, even if the high-mix volume production. Save your master batch, the most expensive material in your production.

Salient Features

- No separation due to conveying.

- Compact and lightweight.

- Accurate blending.

- Reducing master batch.

- Salve labor, time, and resin at the color change.

- The self-control function is built-in.

Descaling Pumps

As a part of the integrated solution, MTIL provides descaling solutions from KAMCO for removing lime scale, rust and corrosion debris from cooling circuits, mold tools, oil coolers, hopper throats, extruder barrels, temperature controllers, and pipework more effectively, in less time.

Salient Features

- High Performance to enable descaling of severely fouled equipment.

- Descaling chemicals safely contained at all times within

- Acid proof: built to handle the strongest descaling chemicals

- Instantaneous flow reverser for increased efficiency.

- No seals to leak, run-dry capability

- Maintenance-free.

- Complete with hoses and fittings.

- 20, 39, 57 & 125 Litres tanks.

- Light and portable.

- Optional fresh water flush facility (FWF) on C 40, C 90, and C 210 models.

All Metal Separator

As a solutions partner, MTIL integrates Metal Separator solutions from MESUTRONIC for installation in free-fall lines in aiming to help our customers to protect their production machines and ultimately their customers from unwanted foreign bodies such as stainless steel, iron, brass, copper, etc. as inclusions or loose parts.

Salient Features

- Reliable - in Process and Detection

- Durable - in Technology and Performance

- Easy - in Installation and Handling

- Digital signal processing for best detection

- Proven for years in rough environments

- Process- and condition monitoring

- High quality, low-wear system components

- Resistant against external influences

- Maintenance-friendly construction

- Size variations for different areas of use

- Perfect fit for flakes and granules

- Understandable operation for all users